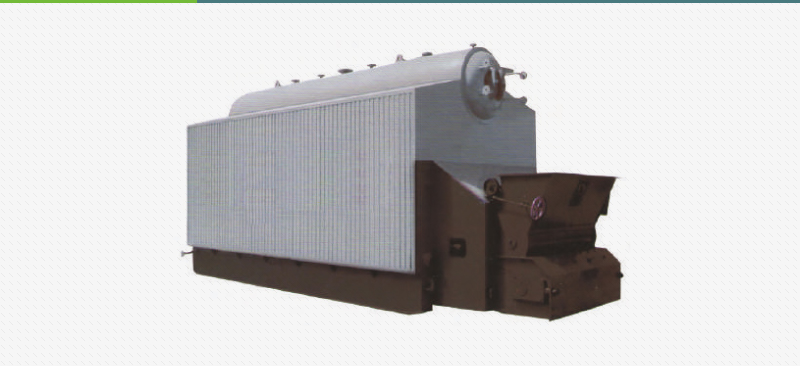

바이오매스+석탄보일러

ESCB SERIES COAL-FIRED STEAM (HOT WATER) BOILER

FEATURES

- 1. The boiler absorbs the advantages of the quick-loading boiler the upper part is composed of the boiler body, the upper furnace wall and the thermal insulation laver, and the lower part is composed of the chain grate and the coal hopper, which is convenient to install and has a short cycle and low cost.

- 2. The boiler has compact structure, small floor space and beautiful appearance. The boiler room only needs to be arranged in a single layer, and the capital construction project has less investment.

- 3. The boiler is easy to operate the operation is stable, the temperature rises and the pressure is fast, the output is sufficient, and the coal is widely used.

- 4. The boiler air supply adopts the warehouse-type double-side Independent air supply device, and each air chamber can be independently adjusted. The air leakage is small and the adjustability is strong, which can better meet the requirements of the combustion characteristics of the chain grate.

- 5. Adopt high standard, high quality auxiliary machine. Accessories and automatic control equipment ensure sale and stable operation of the boiler, while reducing the labor intensity of the furnace.

ESCB series steam boiler technical parameters

| Name\Specification | ESCB6-1.25-A II ESCB6-1.6-A II |

ESCB8-1.25-A II ESCB8-1.6-A II |

ESCB10-1.25-A II ESCB10-1.6-A II |

ESCB15-1.25-A II ESCB15-1.6-A II |

ESCB20-1.25-A II ESCB20-1.6-A II |

ESCB25-1.25-A II ESCB25-1.6-A II |

|

|---|---|---|---|---|---|---|---|

| Rated evaporation(t/h) |

6 | 8 | 10 | 15 | 20 | 25 | |

| Rated steam pressure(Mpa) |

1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | |

| Rated steam temperature(°C) |

194/204 | 194/204 | 194/204 | 194/204 | 194/204 | 194/204 | |

| Feed water temperature(°C) |

60 | 60 | 60 | 105 | 105 | 105 | |

| Heated area(㎡) |

Radiation convection |

29.3/138.8 | 27/170.5 | 22/230 | 39/308 | 58.3/307.4 | 64.8/384.8 |

| Boiler thermal efficiency(%) |

79.6 | 79.2 | 79.6 | 79.1 | 79.6/79.8 | 80 | |

| Boiler fuel consumption(kg/h) |

967 | 1531 | 1904 | 2415 | 3807 | 4272 | |

| Boiler row effective area(㎡) |

7.96 | 10.04 | 11.8 | 17.80 | 22.56 | 24.52 | |

| Boiler transportation large size (Long x Width x High)mm |

8370 x 2960 x 3676 |

6900 x 3430 x 3525 |

7900 x 3430 x 3525 |

9300 x 3430 x 3522 |

11500 x 3430 x 3540 |

12000 x 3430 x 3540 |

|

| Boiler transport large weight(Ton) |

38.5 | 30 | 34 | 44.5 | 55 | 60 | |

EHB SERIES ORGANIC HEAT CARRIER FURNACE

FEATURES

Using coal as fuel and heat-conducting oil as medium, the arculating oil pump is used to force the heat-conducting oil to perform liquid phase circulation, and then the heat energy is transferred to the heat equipment, and the low-temperature oil is retumed to the boiler for reheating Because it can obtain higher working temperature (about 300C) under lower pressure, it can accurately control the working temperature, no need for water treatment equipment, high system utilization, convenient operation and maintenance, is a safe, efficient and energy-saving Heating equipment. Widely used in textile, printing and dyeing, paint drying, chemical, plastics, building materials, artificial leather, wood-based panels, wood production and other industries. It has the following notable features:

- 1. Closed loop circuit is adopted, the heat source is stable, and the heat energy loss is small;

- 2. no need for cumbersome water treatment equipment, long life, easy to control process temperature;

- 3. Low pressure, high outlet temperature, safe and reliable;

- 4. perfect strength design, ample heat transfer area, suitable flow rate inside the pipe, so that the various performances of the boiler are fully guaranteed, easy to operate. convenient for maintenance and repair.

EHB series organic heat carrier furnace the main technical parameters

| Parameter | Data | Model | EHB- 1200MA (100*104 kcal) |

EHB- 1400MA (120*104 kcal) |

EHB- 2000MA (160*104 kcal) |

EHB- 2400MA (200*104 kcal) |

EHB- 3000MA (250*104 kcal) |

EHB- 3500MA (300*104 kcal) |

EHB- 4100MA (350*104 kcal) |

EHB- 4700MA (400*104 kcal) |

EHB- 6000MA (500*104 kcal) |

EHB- 7000MA (600*104 kcal) |

EHB- 8200MA (700*104 kcal) |

EHB- 9300MA (800*104 kcal) |

EHB- 12000MA (1000*104 kcal) |

EHB- 14000MA (1200*104 kcal) |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rated thermal power(KW) |

1200 | 1400 | 2000 | 2400 | 3000 | 3500 | 4100 | 4700 | 6000 | 7000 | 8200 | 9300 | 12000 | 12500 | |

| Thermal power(%) |

≥78 | ≥78 | ≥79 | ||||||||||||

| Design pressure(Mpa) |

1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | |

| Maximum working temperature(°C) |

320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | |

| Cycle oil volume(㎥/h) |

100 | 100 | 160 | 180 | 200 | 200 | 250 | 250 | 340 | 340 | 400 | 520 | 600 | 600 | |

| Piping connection Diameter(mm) |

125 | 150 | 150 | 150 | 150 | 150 | 150 | 200 | 200 | 200 | 250 | 250 | 310 | 310 | |

| Full system installed capacity(KW) |

49.5 | 49.5 | 75 | 75 | 87 | 89 | 110 | 135 | 180 | 180 | 220 | 250 | 310 | 310 | |

| Coal burning type |

MA II, III | ||||||||||||||

| Coal weight(kg/h) |

235 | 300 | 400 | 470 | 565 | 655 | 757 | 900 | 1123 | 1390 | 1952 | 2210 | 2290 | 2900 | |

| Shpae | Length(mm) | 4710 | 4710 | 5821 | 5821 | 6814 | 6814 | 6814 | 7214 | 8734 | 9156 | 10050 | 11300 | 11794 | 13608 |

| Width(mm) | 2020 | 2020 | 2020 | 2020 | 2020 | 2500 | 2500 | 2500 | 3040 | 3200 | 3200 | 3200 | 3300 | 3320 | |

| Size | High(mm) | 3608 | 3808 | 4040 | 4349 | 4487 | 4487 | 4846 | 4874 | 5236 | 5287 | 5432 | 5432 | 6070 | 6070 |

| Total weight(kg) | 17000 | 18000 | 25000 | 26100 | 34000 | 38600 | 40000 | 45000 | 59000 | 70000 | 86500 | 95400 | 105000 | 117500 | |